Exactly How Stretch Wrapper Repair Functions: A Comprehensive Overview to Keeping Your Tools Practical

Stretch wrapper repair is vital for preserving the effectiveness and dependability of product packaging operations. Specialists usually encounter different issues that can hinder performance. A methodical approach is crucial for effective repair services. Recognizing typical issues and having the right devices can make a significant difference. Furthermore, recognizing when to perform preventative upkeep can prolong devices life. This guide checks out the intricacies of stretch wrapper fixing and what it takes to keep equipment in ideal condition.

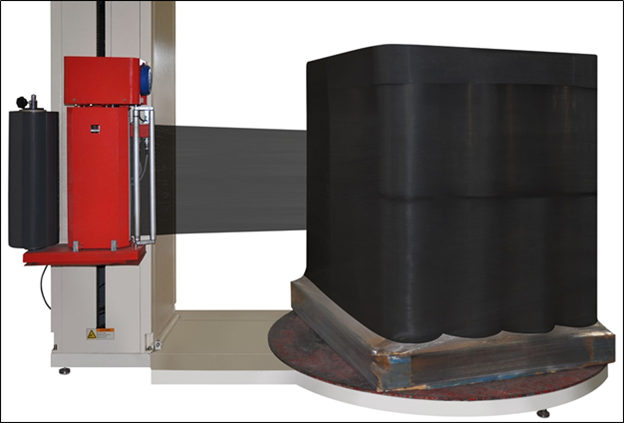

Understanding Common Stretch Wrapper Issues

As the demand for reliable product packaging solutions raises, understanding common stretch wrapper problems ends up being vital for preserving functional effectiveness. Stretch wrappers frequently encounter several widespread troubles that can interfere with workflow. One typical concern is irregular film stress, which can lead to inadequate tons stability. This disparity might be due to misaligned setups or worn-out components. stretch wrapper repair. Additionally, movie tearing frequently takes place, leading to lost materials and time. Incorrect packing methods or inappropriate movie kind can add to this problem.Another issue involves the machine's electrical components, which can malfunction and cause functional delays. Routine upkeep is important to ensure that electronic systems, such as electric motors and sensing units, function correctly. Ultimately, mechanical jams might happen, often coming from debris build-up or worn equipments. Understanding of these issues enables drivers to proactively address them, ultimately improving the reliability and performance of stretch covering operations

Tools Required for Stretch Wrapper Repair Works

Effective repairs on stretch wrappers require a specific collection of tools tailored to address the usual issues recognized earlier. Crucial tools consist of an outlet and wrench set for loosening and tightening bolts, which is critical for accessing internal components. A multimeter is necessary for identifying electrical troubles, allowing service technicians to determine voltage and connection in the system. Furthermore, screwdrivers of various dimensions are essential for eliminating panels and accessing parts that might need substitute or adjustment.A measuring tape aids ensure exact positioning throughout repair work, while pliers can help in gripping and controling smaller parts. Lubricants and cleaning up representatives are additionally necessary for maintaining smooth operation and stopping wear. Finally, safety and security gear such as handwear covers and goggles must be included to shield the specialist throughout the repair work process. By furnishing themselves with these tools, technicians can effectively deal with a variety of concerns that may occur in stretch wrappers.

Step-by-Step Fixing Refine

Begin the repair service process by making sure the stretch wrapper is powered off and detached from the electrical supply. Next, inspect the equipment for visible signs of damages or wear, concentrating on key components such as the film carriage, rollers, and sensors. Eliminate them carefully using appropriate tools.Document the disassembly process to assist in reassembly if any kind of parts appear malfunctioning. Change harmed components with OEM parts to maintain performance requirements. After setting up brand-new parts, reassemble the device, making sure all links are safe and secure and aligned properly.Once reconstructed, conduct a comprehensive inspection of all arrangements and settings - stretch wrapper repair. Power the device back on and run an examination cycle to validate functionality. Focus on any uncommon audios or malfunctions throughout procedure. If necessary, make additional changes or seek advice from the maker's guidebook for troubleshooting. Correctly record the fixing process for future referral

Preventative Upkeep Techniques

Implementing preventative maintenance methods is necessary for lengthening the life-span of a stretch wrapper and guaranteeing peak performance. Normal assessments ought to be performed to identify any indications of wear or damage, concentrating on critical components such as sensors, motors, and belts. Cleaning the device regularly assists avoid debris accumulation, which can hamper procedure. Oiling relocating components based on the manufacturer's guidelines lowers friction and prolongs the life of mechanical elements.Furthermore, preserving correct stress on the film and guaranteeing that the film rolls are stored appropriately decreases strain on the devices. Operators ought to be trained to recognize uncommon sounds or motions throughout procedure, as these can suggest prospective concerns before they escalate. Developing an upkeep timetable that consists of replacing used parts proactively can substantially minimize the threat of unexpected break downs. By sticking to these methods, services can improve the integrity and efficiency of their stretch wrappers.

Repairing Tips for Quick Fixes

In attending to typical stretch wrapper issues, fast repair strategies play a crucial role in reducing downtime. By comprehending the typical problems that emerge, operators can carry out effective maintenance ideal practices. This section will discover practical options for quick troubleshooting.

Usual Stretch Wrapper Issues

Quick Repair Service Techniques

Maintenance Ideal Practices

While regular maintenance is vital for excellent performance, implementing ideal methods for repairing can Clicking Here likewise result in fast solutions. Identifying and dealing with typical problems quickly is important. Operators needs to acquaint themselves with the stretch wrapper's handbook, as it commonly has valuable troubleshooting ideas. Frequently examining components like rollers, belts, and electric links can protect against minor problems from escalating. Maintaining a log of repeating issues assists determine patterns and services. In addition, preserving a tidy workspace minimizes the threat of particles impacting tools functionality. When coming across an error, rebooting the device can fix several short-term glitches. Utilizing maker sources and on-line discussion forums can likewise use fast understandings from experienced individuals, ensuring that devices continues to be functional with minimal downtime.

When to Call an Expert Specialist

When should one think about reaching out to an expert service technician for stretch wrapper repairs? Commonly, a specialist should be gotten in touch with when the devices experiences relentless concerns that can not be fixed via fundamental troubleshooting. For circumstances, if the stretch wrapper consistently stops working to run, displays mistake codes, or if parts such as the electric motor or control board program signs of damages, professional aid is necessitated. In addition, if the machinery requires specialized devices or knowledge for repair work, enlisting a specialist guarantees a correct resolution.Moreover, when the repair service tries cause more intricate issues or when downtime influences manufacturing routines considerably, specialist treatment may be necessary. Routine maintenance checks can aid in identifying potential concerns early, but once a breakdown happens that exceeds the driver's ability set, it is prudent to call a specialist. This technique not only ensures reliable repair work yet also keeps functional efficiency and security within the office.

Finest Practices for Tools Long Life

To assure the durability of stretch wrapping tools, a routine maintenance timetable is vital. Abiding by appropriate use techniques likewise plays a vital duty in lessening wear and tear. Executing these finest techniques can substantially extend the life expectancy of the machinery.

Routine Maintenance Arrange

A well-structured normal maintenance schedule is essential for making certain the durability of stretch wrapping equipment. This timetable must include daily, weekly, and monthly jobs customized to the details model and use problems. Daily assessments need to concentrate on examining for indications of wear, ensuring appropriate tension, and verifying that safety attributes are functional. Weekly maintenance can include cleaning up the machine and lubricating relocating components to minimize friction. stretch wrapper repair. Month-to-month evaluations ought to incorporate an extensive exam of electric elements and drive systems. Keeping thorough records of upkeep tasks aids in identifying patterns or persisting problems, helping with prompt interventions. Complying with this schedule not just prolongs devices life however also improves efficiency, reducing downtime and repair work prices

Appropriate Use Methods

Regular upkeep is only one element of making the most of the lifespan of stretch wrapping equipment; correct usage strategies additionally play a significant duty in enhancing efficiency and toughness. Operators needs to be trained sufficiently to assure they recognize the equipment's constraints and capabilities. Regularly sticking to the supplier's standards for load dimensions and covering patterns is vital. Furthermore, preserving a clean operating atmosphere assists avoid debris build-up, which can hinder the device's efficiency. It is important to check the stress setups to stop over-stretching or under-stretching the movie, both of which can lead to inefficient covering. Confirming that the devices is operated within its specified specifications will lessen wear and tear, eventually expanding its functional life and lowering the demand for repairs.

Often Asked Concerns

How Often Should I Execute Regular Maintenance on My Stretch Wrapper?

Routine upkeep on a stretch wrapper should preferably be carried out every three to six months, depending upon usage. Normal checks can avoid failures and guarantee peak efficiency, expanding the maker's lifespan and enhancing operational efficiency.

What Are the Signs Showing My Stretch Wrapper Requirements Immediate Repair?

Indicators that a stretch wrapper calls for immediate fixing include unusual sounds throughout operation, inconsistent covering stress, mistake messages on the control panel, and visible damage to elements, showing prospective failing that calls for prompt focus to stop more concerns.

Can I Use Any Lubricating Substance for My Stretch Wrapper Components?

Making use of any type of lubricating substance on stretch wrapper components may bring about issues. It is vital to make use of manufacturer-recommended check out here lubricants to assure peak performance and protect against damages, as incompatibility can cause malfunctions and raised upkeep expenses.

Just how Do I Pick the Right Stretch Wrap for My Equipment?

Choosing the appropriate stretch wrap includes considering maker requirements, lots kind, and environmental variables. Reviewing width, stretchability, and density guarantees optimal efficiency, preventing damage while maintaining item integrity throughout storage and transportation. Correct selection is necessary.

Is It Safe to Run a Malfunctioning Stretch Wrapper Temporarily?

Operating a malfunctioning stretch wrapper, even briefly, presents significant security threats. It can lead to more tools damages and increase the probability of crashes, jeopardizing both driver security and total performance in the workplace. As the need for efficient packaging solutions boosts, recognizing usual stretch wrapper concerns comes to be essential for keeping operational efficiency. Reliable repair work on stretch wrappers require a particular collection of tools tailored to address the typical concerns determined earlier. In dealing with common stretch wrapper concerns, quick fixing methods play a crucial function in decreasing downtime. Addressing these common stretch wrapper problems quickly ensures minimal downtime, preserving productivity and performance in packaging procedures. Making look here use of any kind of lubricant on stretch wrapper components might lead to problems.